- GEAR

- SPARE PARTS

- Backcountry Kit

- Pro Backcountry Kit

- Binding Hardware Kit

- Pro Binding Hardware Kit

- LT Bracket

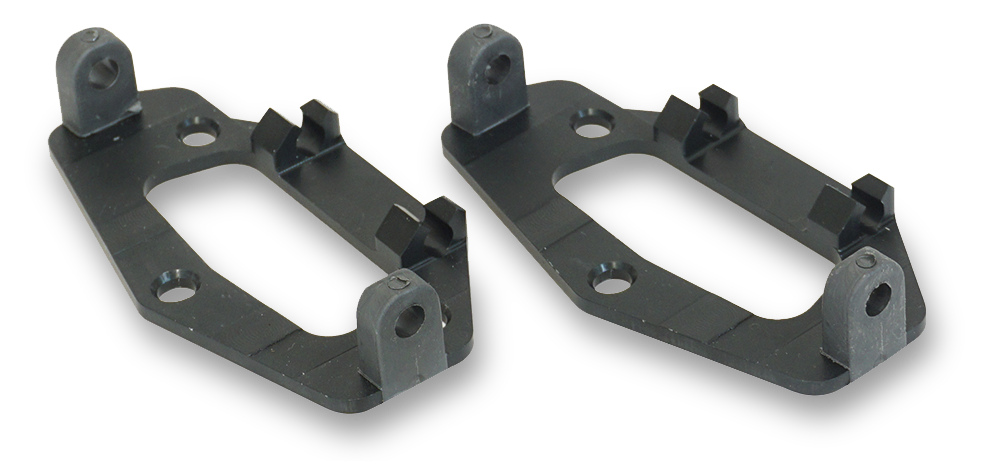

- Snap Block

- ST Bracket

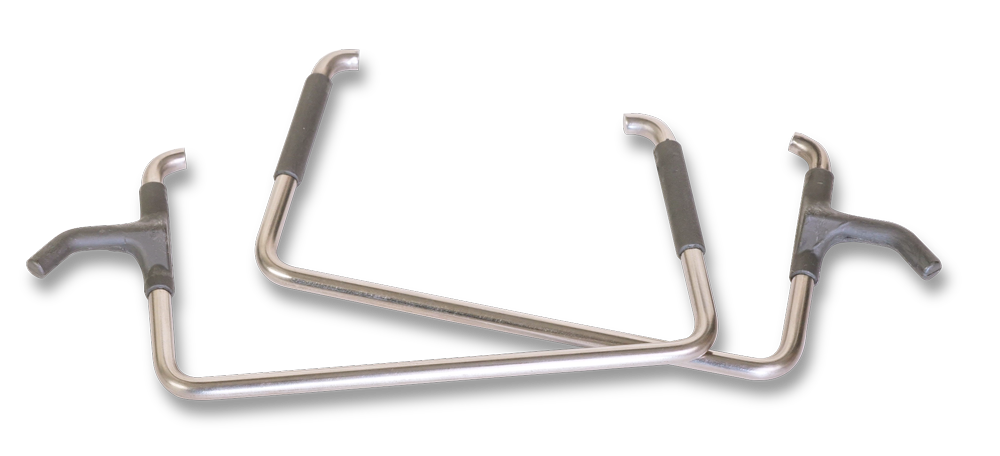

- T1 Heel Rest

- Ankle Buckle

- Toe Buckle

- Ankle Ladder

- Toe Ladder

- Ankle Adjuster

- Toe Adjuster

- Vert Pucks

- Stainless Steel Pin

- Mini Puck Alignment Guide

- Puck Alignment Guide

- Spark Skin Trimmer

- BINDING TECH

- FAQs

- DEALERS

- TEAM RIDERS

- CONNECT

- ABOUT US

- CONTACT US

Dedicated to pushing innovation in splitboarding since 2006.

866.725.2085

Email: sales@sparkrandd.com

Spark R&D

P.O. Box 3284, Bozeman, MT 59772 USA

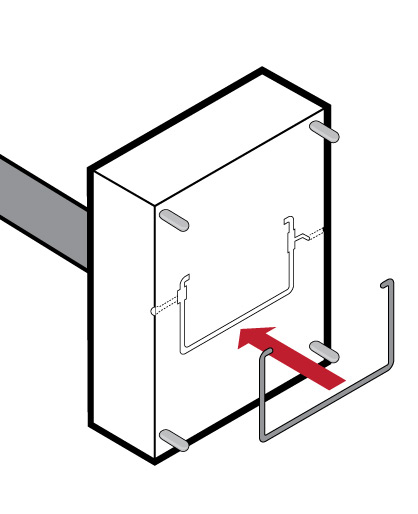

We have enhanced several of our binding and crampon components using a manufacturing technique called overmolding. By injection molding a proprietary thermoplastic blend over and through existing aluminum or steel parts several key areas of friction and wear are eliminated.

Our team created their own custom thermoplastic blend specific to the overmold process that includes additives to make it extremely cold tolerant, durable, and abrasion-resistant.