Dedicated to pushing innovation in splitboarding since 2006.

866.725.2085

Email: sales@sparkrandd.com

Spark R&D

P.O. Box 3284, Bozeman, MT 59772 USA

Spark R&D is Expanding!

A Second Building Allows for More Machines, More People, and Much Needed Storage

We bought another building! It may be a short sentence, but it was a long process.

We’re pleased to announce that last October, we finalized the purchase of a second 7,000 sq/ft building across the street from the 12,000 sq/ft building we’ve utilized for over ten years. We explored numerous options for expansion, including building another facility, but ultimately, we were able to work with a local family that owned the building adjacent to us. This building has housed multiple businesses over the last 3 decades under their ownership, and it feels nice to become stewards of the building putting the space to good use.

You may be wondering why we’re just announcing this now, and the answer is simple: first, the building was not move-in ready and we’ve been putting a lot of time and effort into making the space usable, and second, we’ve been busy making splitboard bindings!

We completed the purchase and moved a lot of product and people to the new building during our busiest (and most challenging) production season to date. While we remain busy as we prepare for the upcoming season, now is as good a time as any to make the announcement. Splitboarding is growing and so is Spark R&D!

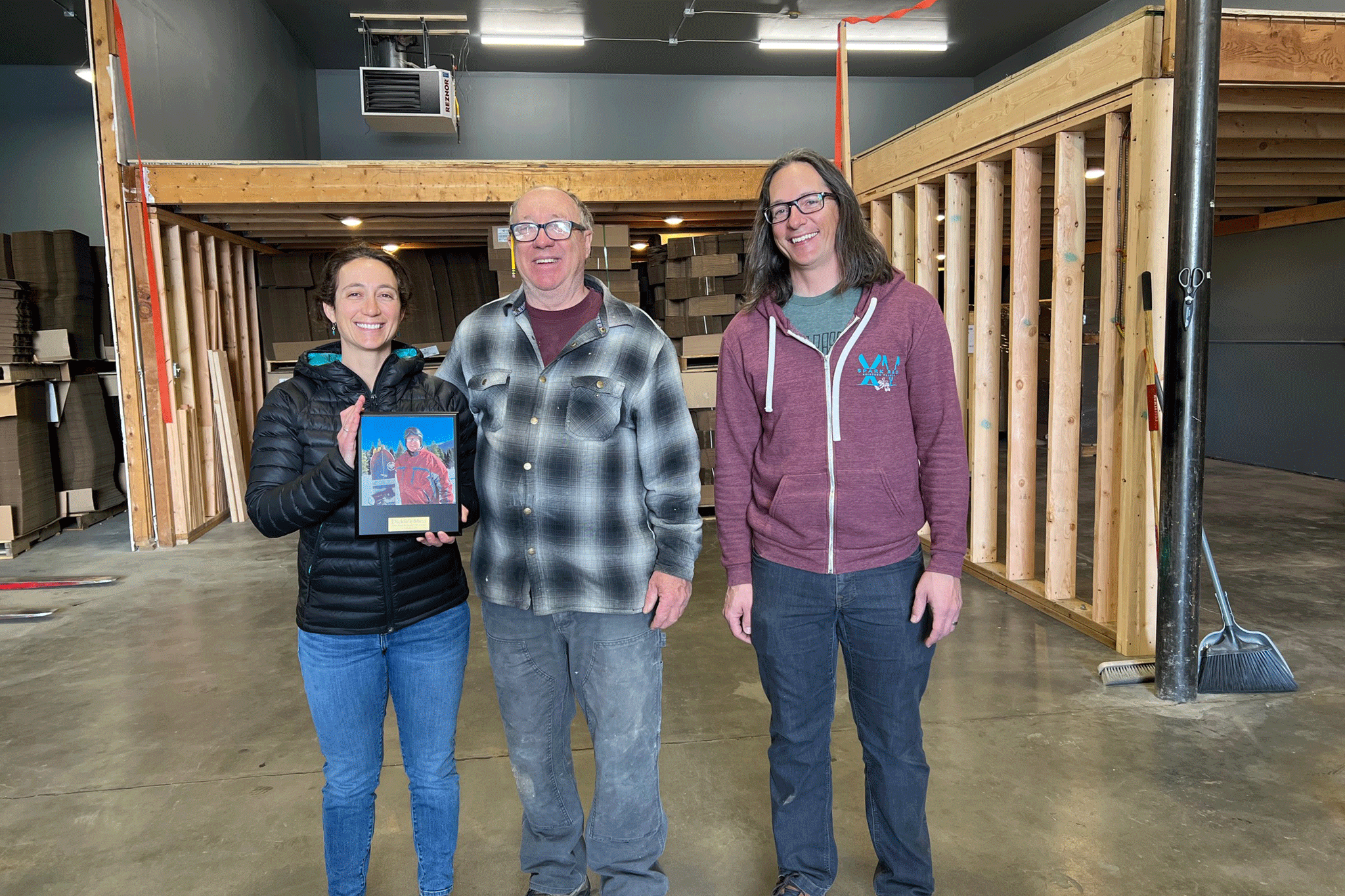

Closing on the New Building

A lot of work lead up to this day! Here Becca and Will close on the new property.

Becca and Will Ritter

Moments after finalizing the purchase!

Becca Ritter

Mandatory key shot.

With the addition of the building, a new chapter begins for Spark R&D. We now have a campus! Well, kind of.

The new building helps us in 4 important ways:

More Machines!

First, it allows us to add more machines. More machines means more parts, and more parts means more bindings! We’ve moved the entire finished product warehouse, along with the shipping, customer service, sales, and marketing teams to the new building. This has freed up space for a couple of new additions to the machine shop with room for a few more. To date, we’ve already added another EC-400 horizontal milling machine with a 7-pallet changer along with an Automatic Lathe screw machine.

The New EC-400

This is our new EC-400 with 7 pallet changer! We now have 2 of these machines at Spark. They're freakin' awesome!

The Pallet Changer

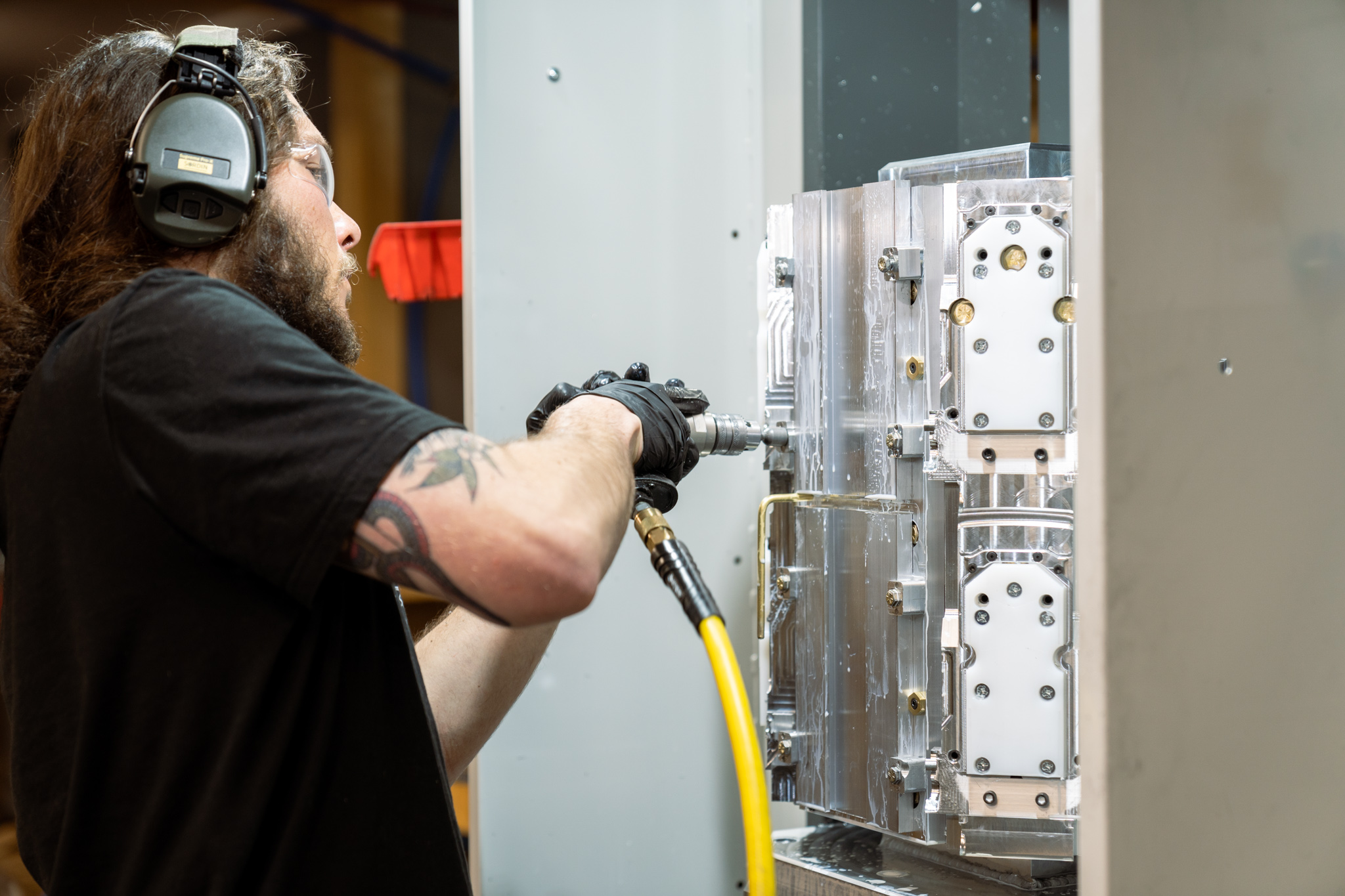

Derek, one of the many excellent machinists we have at Spark, working on the pallet changer.

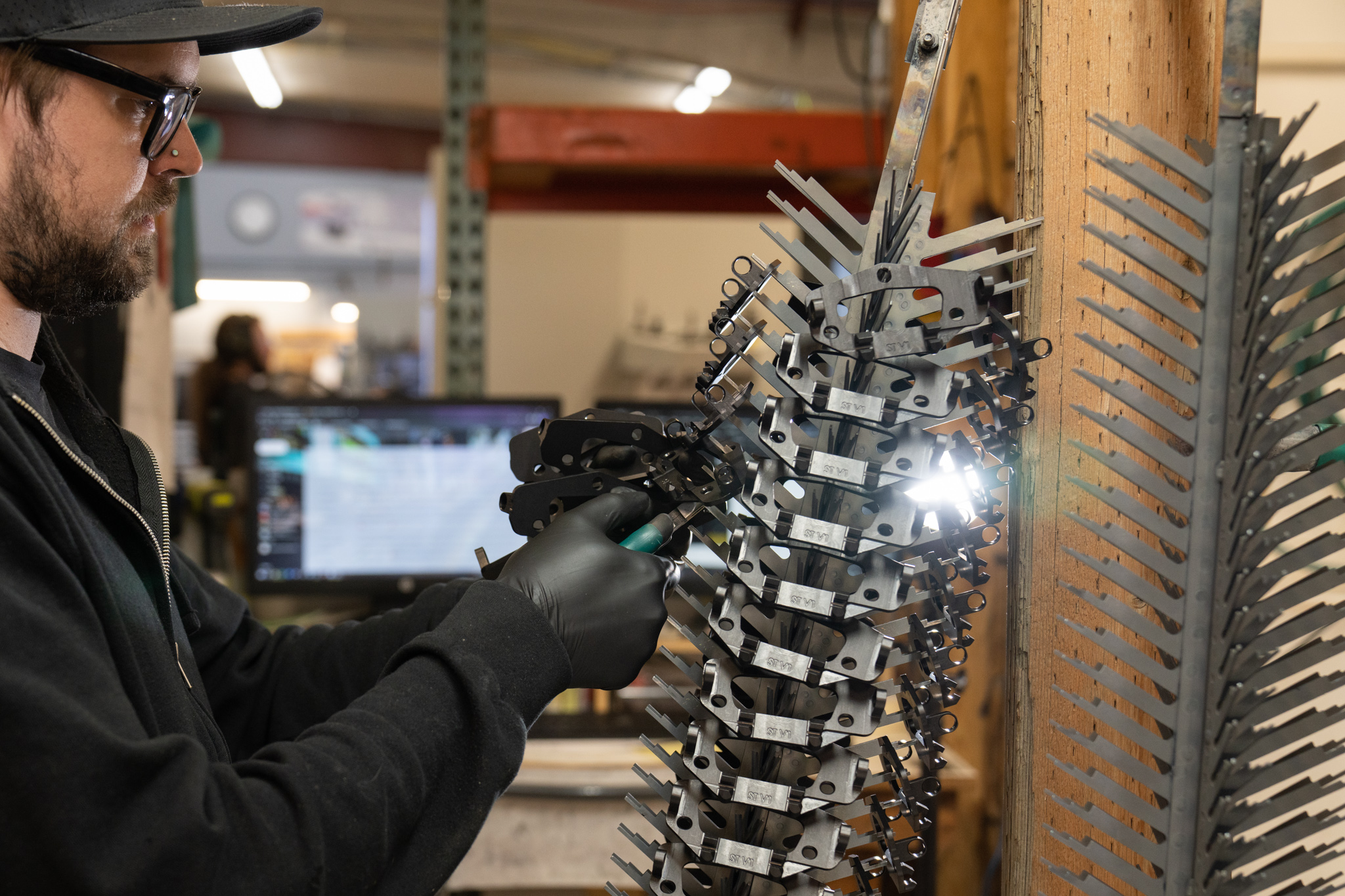

Machinist: Kylie Torgrimson

The new machines produce tons of baseplates. Each one is QC'd and filed before continuing its journey to become a binding.

Machinist: Billy Madej

Billy is one of our newer machinists and has become an expert on the Auto Lathe.

A Baseplate Pin

We make almost all of our parts in-house. The screw machines make our smallest parts like t-nuts for straps, baseplate pins, and pro aluminum hardware.

Our new Automatic Lathe can handle multiple pieces of stock whereas our older machines can only operate with a single piece at a time.

Spark, what the heck is an EC-400 horizontal milling machine and an Automatic Lathe screw machine?

Why are these good?

Great question, The EC-400 is a large milling machine that makes many of our important parts like baseplates and puck disks. As you might imagine, we make A LOT of these parts. We order custom aluminum extrusion, we cut it to size, and then load this in our machines. The milling machines remove material until we have the basic shape of one of our parts. Our new EC-400 makes excellent parts, but the biggest advantage of this particular machine is the pallet changer. With the 7-pallet changer, one machinist can load up all the pallets with raw stock and let a single program run unattended for 8-hours at a time helping Spark to run 24-hours a day.

Our screw machines produce most of the small pieces you see on our bindings and accessories. Think pivot pins, t-nuts for straps, and pro hardware. The new Automatic Lathe is just a really good screw machine that produces better parts and more of them.

More People!

Secondly, it may sound obvious, but if you want to build more bindings, you need more people. We have 80+ people working at Spark now. It takes a lot of awesome people to make this whole thing happen, and no one wants to be working right on top of one another. The new building has spread everyone out a little. And the parking! We added a bunch of new parking with the new building too!

The Spark Crew!

We've assembled an awesome team here in Bozeman, MT!

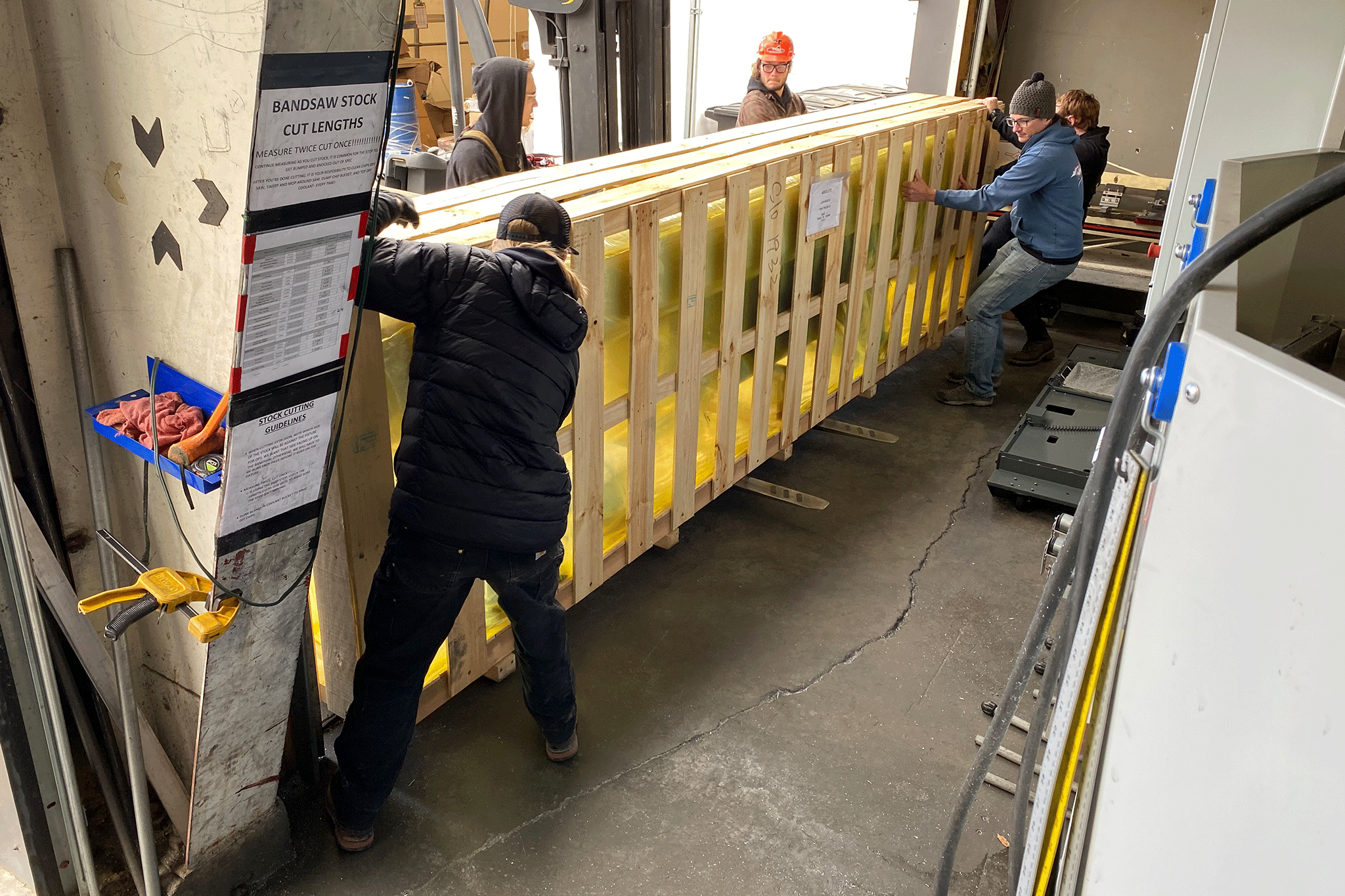

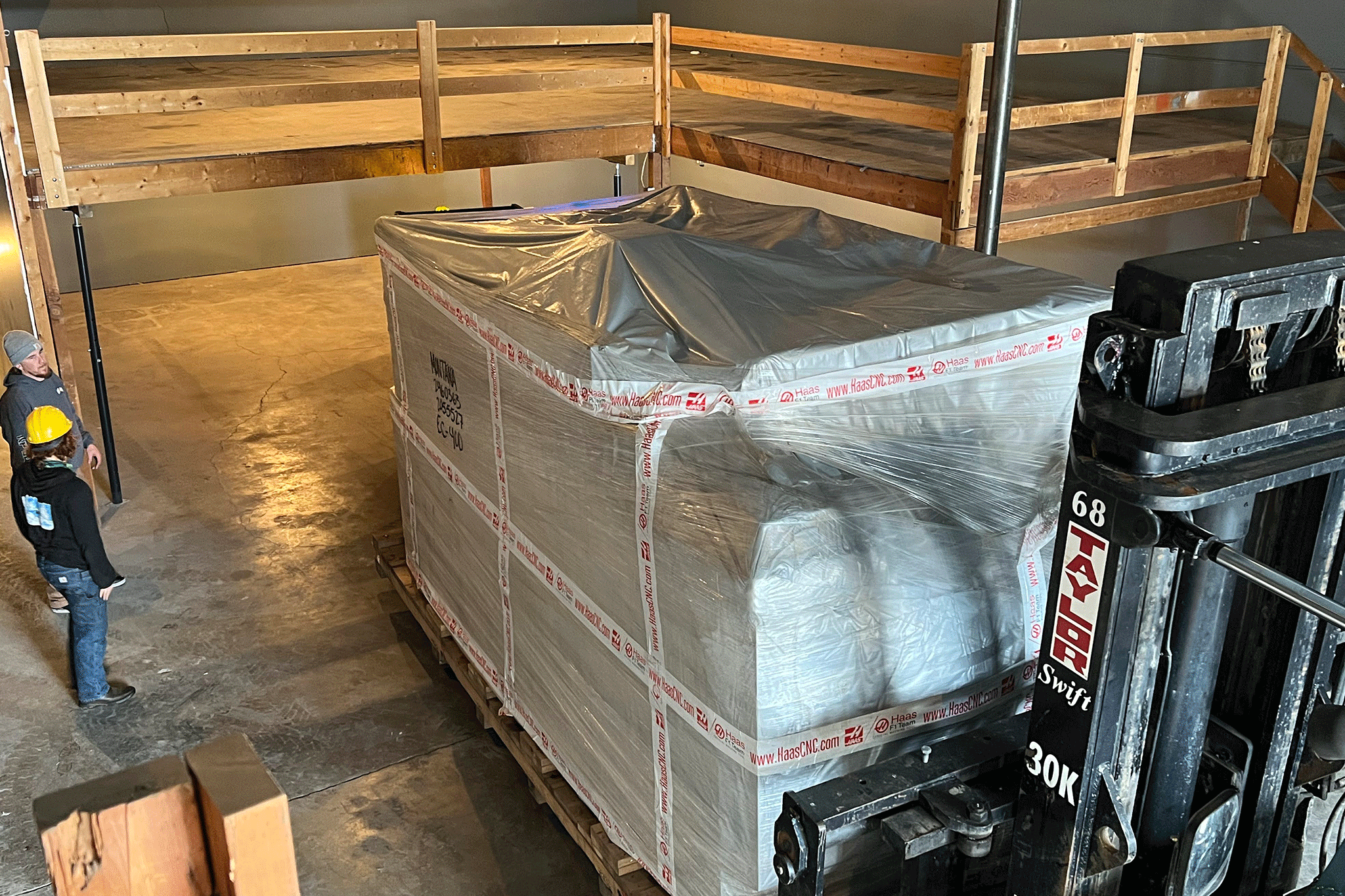

Teamwork!

The team works together to bring in our new Automatic Lathe screw machine.

Assembly and Pre-Assembly Rock Stars

Some of our assembly and pre-assembly team in what was formerly our finished product warehouse.

More Storage!

Thirdly, we now have space to store more raw materials. One of the supply chain challenges of the last year is that we have to order materials earlier, and more importantly, we have to order muuuuch larger quantities at one time. Ordering more of something may seem like an easy solution, but you need to have somewhere to store it. Fifty pallets of cardboard and 20,000 lbs. of aluminum extrusion takes up quite a bit of space. We rebuilt and reinforced the mezzanine in the new building and now have ample storage space for everything.

Becca, Will, and Dick

Dick is Becca's father and the master mezzanine builder! The rebuilt mezzanine has been dubbed Dickies' Mezz!

Raw Materials Take Up a Lot of Space

Raw aluminum extrusion in the foreground, Dickies' Mezz and most of our Hitchhiker components in the background.

EC-400 When it First Arrived

The new space has helpful in a lot of ways - like last winter when we had to store one of the new machines in it for a few weeks before the shop was ready.

A New Forklift for a New Building

What? Maybe we get excited about forklifts...

The New Finished Products Warehouse

Our new building is broken into 2 halves, this is the finished products warehouse side which also houses our shipping, sales, marketing, and design teams.

Future Growth!

Lastly, the new building allows us to plan for the future. We bought ourselves time to grow, and we’re quickly utilizing the additional space as we move into next season’s production run. We now have some flexibility, increased capacity, and some room to breathe.

JP on the Forklift

Cross-campus moves are now commonplace at Spark to get materials where they need to be.

Cutting Raw Stock.

22/23 Surge ST

A sneak peek for everyone that has read this far! The 22/23 Surge ST has Asymetrcial Rip 'N' Flip Highbacks.

22/23 Arc ST

We're pretty stoked on the Arc ST graphics for next season.

The future is bright for Spark R&D! Our new building is the key to growing our business and taking Spark to the next level. It wasn’t that long ago that we were sharing a small 4,000 sq/ft shop with another local manufacturer.

We’re excited about the opportunities the new space provides, and, we’re excited not to have to think about expanding for a while. It’s time to concentrate on what we’re best at – making splitboard bindings and accessories.

Read more +16 September 2022 in Inside Spark, Instructions, Technology

Read more +16 September 2022 in Inside Spark, Instructions, Technology